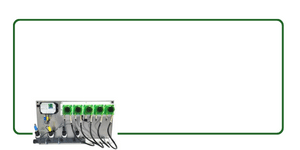

BDX BatchMatic™ Fertigation Systems are batch-type nutrient mixing systems for multi-zone greenhouse irrigation and hydroponics facilities. Automatically mix recipes and correct pH according to your schedule, then send the batches to the programmed zones. Use the system to directly feed up to 14 zones of plants or send recipes to holding tanks.

Available with either 5, 6, 10 or 12 chemical pumps. Each pump can be configured for EC nutrient dosing, pH up, pH down, or ORP as required. Precision sensors and rugged pumps offer reliable and accurate control. Built with FDA compliant tubing, the dosing pumps inject chemicals quickly and precisely.

The controller's large built-in color touch screen display provides an easy to use interface for monitoring the sensor readings and configuring the dosing settings. Display includes features such as:

- Current batch status, recipe, stage, etc.

- Pause, continue, skip & run-now features for manual control

- Sensor / system monitoring & display

- Schedule event configuration

- Recipe editing and creation

- Alarm settings and configuration

- Email account & recipient settings

- Guided sensor calibration screens

- Manual pump priming and system diagnostics

- User accounts & login screen

These pre-assembled panels come ready to dose! Just mount, plug in power and plumb the water connections! Customer must supply a mixing tank between 55 - 1000 gallon capacity and install the level sensors in the tank.

BDX BatchMatic™ Fertigation Systems are batch-type nutrient mixing systems for multi-zone greenhouse irrigation and hydroponics facilities. Automatically mix recipes and correct pH according to your schedule, then send the batches to the programmed zones. Use the system to directly feed up to 14 zones of plants or send recipes to holding tanks.

Available with either 5, 6, 10 or 12 chemical pumps. Each pump can be configured for EC nutrient dosing, pH up, pH down, or ORP as required. Precision sensors and rugged pumps offer reliable and accurate control. Built with FDA compliant tubing, the dosing pumps inject chemicals quickly and precisely.

The controller's large built-in color touch screen display provides an easy to use interface for monitoring the sensor readings and configuring the dosing settings. Display includes features such as:

- Current batch status, recipe, stage, etc.

- Pause, continue, skip & run-now features for manual control

- Sensor / system monitoring & display

- Schedule event configuration

- Recipe editing and creation

- Alarm settings and configuration

- Email account & recipient settings

- Guided sensor calibration screens

- Manual pump priming and system diagnostics

- User accounts & login screen

These pre-assembled panels come ready to dose! Just mount, plug in power and plumb the water connections! Customer must supply a mixing tank between 55 - 1000 gallon capacity and install the level sensors in the tank.